Learn what packaging fillers are and the different types businesses use to ship products.

Packaging fillers refer to materials used to fill gaps in a shipping box to protect its content. They act as cushions should the box get hit or dropped during transport. People also call them void fill, box cushioning, and box padding.

In today's post, you'll learn if you need to use packaging fillers. You'll also discover the different packaging fillers businesses use to ship products.

Do You Need Packaging Fillers?

It all depends on the type of products you ship. Apparel products like shirts, hoodies, pants, shorts, and jackets don't need packaging fillers because they're less likely to get damaged during transport. These types of products will be fine if shipped using poly mailers.

Fragile products like electronics and glassware, however, need packaging fillers. They'll give you peace of mind as your products make their way to customers.

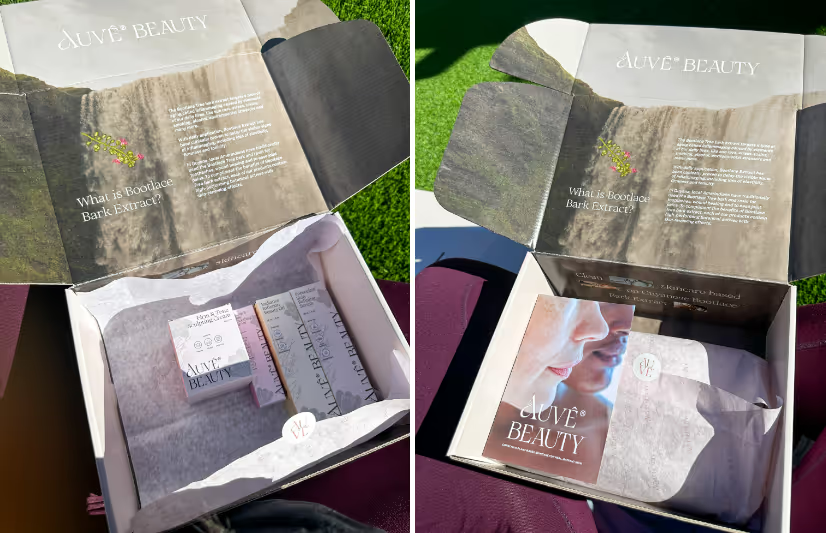

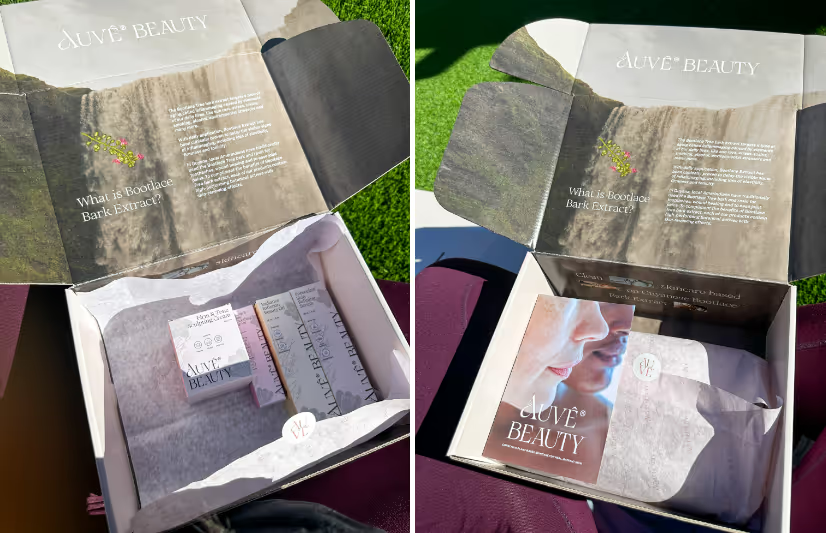

You should also consider using packaging fillers if branding is a priority for your company. Branded packaging fillers add credibility to your business and keep products free from damage and dirt.

Below are other reasons why you might need packaging fillers:

- Improve the Unboxing Experience — Customers appreciate it when businesses make their unboxing experience feel special. Fillers can create excitement as customers dig their way through filler material to reveal the products they bought.

- Keep Contaminants Away From Your Product — You can't expose certain products to contaminants, light, heat, air, moisture, and other elements that affect product quality. Packaging fillers do a great job of preventing exposure during shipping.

- Comply With Legal Requirements — Shipping liquid and perishable products requires businesses to use multiple layers of packaging to make room for cooling gels, dry ice, or other refrigerants. You'll have to use packaging fillers to keep products from rattling inside their casing.

Consider all these factors when deciding whether to use packaging fillers or not.

How to Choose the Right Packaging Filler?

There are several types of packaging filler you can use when shipping products. How will you know which one is best for you?

Here are some factors you have to consider.

Price

Some packaging fillers cost more than others. You'll have to factor in pricing when sourcing box packaging fillers.

Sustainability

Brands with sustainability in mind must avoid packaging fillers that aren't eco-friendly. Fortunately, there are plenty of fillers that customers can easily recycle.

Customization Options

You can customize some packaging fillers to feature your branding or fit your product packaging perfectly.

Versatility

There are rigid packaging fillers like styrofoam that are only good for specific products. Those who want to use fillers for different products should look for something versatile.

Types of Packaging Fillers

Here's a list of the most popular packaging fillers for shipping products.

Packing Peanuts

Packing peanuts are small, lightweight styrofoam packaging fillers. These are great at absorbing impacts and vibrations during shipping. They're effective at filling gaps, even if products don't have a uniform shape or size.

It also helps that packing peanuts are relatively inexpensive. However, traditional packing peanuts are not biodegradable.

Air Pillows

Air pillows are inflatable packaging fillers that protect products from sudden impact during transport. They're just as good as other packaging fillers.

One of the downsides of using air pillows is that they're at risk of getting punctured along the way, especially if your products have pointy or rough edges. Some air pillows are also non-biodegradable.

Tissue Paper

Tissue Paper Design by Those Moments Design Co.

Tissue papers are customizable and recyclable. That makes them a fantastic choice for packaging filler. You can personalize tissue paper to have your logo or other branding elements.

They only provide limited cushioning though. You can wrap them around products like jars and other glassware. But you can only use them for smaller items.

Fabric

Source

You can use cotton, linen, or polyester fabric bags as packaging fillers. These look amazing when customized and they're reusable too. They provide soft cushioning — ideal for soap bars, jewelry, and specialty items.

They can, however, add weight to your packaging which will increase shipping costs.

Packing Paper

Packing paper is made from recycled paper and comes in different sizes, weights, and formats. This packaging filler is versatile because you can wrap products in it or pack sheets around your product to secure it into place.

This material also offers limited cushioning so it's unsuitable for more fragile items.

Bubble Wrap

Bubble wrap is another popular option. They're versatile and lightweight. It can also resist moisture. People are already familiar with bubble wraps and expect businesses to use them for added protection.

There are biodegradable bubble wraps though they're less popular.

Styrofoam

Styrofoam is rigid but effective at absorbing impact. It also has thermal insulation properties. The main problem with styrofoam is that it's hard to deal with after use. Customers don't like that they tend to create static electricity, making it cling to surfaces.

This packaging filler is also non-biodegradable.

Recap

Packaging fillers are materials used to fill gaps in shipping boxes. You need packaging fillers to prevent products from getting damaged during transport. Price, sustainability, customization options, and versatility are factors you must consider when choosing packaging fillers.

Today's most popular packaging fillers are packing peanuts, air pillows, tissue paper, fabric, bubble wrap, and styrofoam.

Do you need custom product or shipping boxes for your business? Call us if you'd like to get a quote. You can also email us at sales@packm.com or use our live chat feature.

Related Posts